IZONIL Hard: hydrophobic and simultaneously vapor-permeable render of a new generation

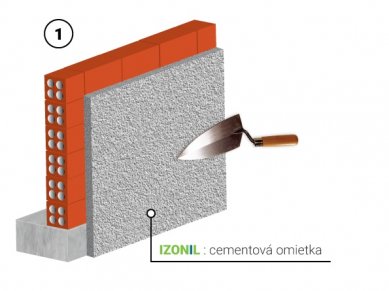

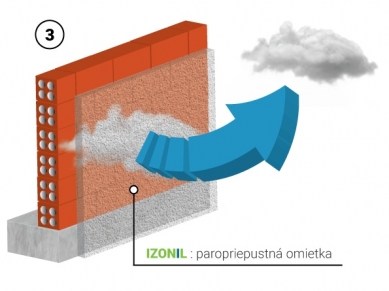

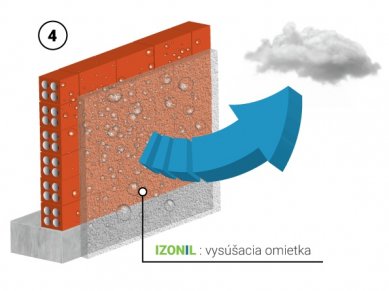

The development of construction materials is constantly moving forward, including plasters. The product IZONIL Hard, developed and manufactured in Slovakia, represents a dry, industrially produced plaster that is hydrophobic due to its world-unique composition, while also being highly vapor permeable and exceptionally effective at drying.

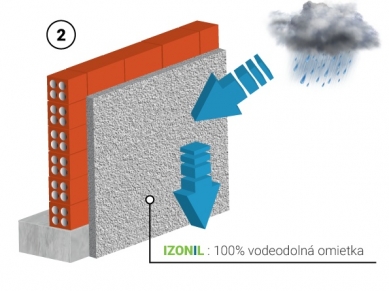

In situations where water infiltrates a house (for example, during floods or due to heavy rainfall), serious structural problems or health complications caused by mold growth may arise. For the product to be effective in combating these unwanted complications, it is not enough for it to be merely water-repellent. Its functionality is significantly influenced by its vapor permeability. Both requirements are met by the plaster IZONIL Hard, which primarily consists of Portland cement, silica sand, and a unique additive called Izocomponent. It is reinforced with PP fibers and can be used in both interior and exterior applications. The plaster is non-toxic (suitable for direct contact with drinking water) and can also be applied to damp surfaces. Application can be done manually or with a plastering machine, and due to the excellent adhesion of this plaster, minimal waste is produced during its application.

The plaster can be used on vertical substrates (brick, aerated concrete, and roughened concrete walls), horizontal substrates (concrete floors and roofs), waterproofing and remediation of basements and other underground spaces, during the renovation of plasters in old buildings, waterproofing of bathrooms and shower stalls, and also as a means to prevent water from seeping between floors. The IZONIL Hard plaster is invaluable for its versatility, quality, and reliability in nearly any construction. It is manufactured in two standard variations: F010 Fine (grain size 0-0.6 mm / 25 kg) and C020 Coarse (grain size 0-2 mm / 25 kg).

Distributor for the Czech Republic and Slovakia:

RBL Trade s. r. o.

Štefánikova 81

085 01 Bardejov

Slovakia

Company ID: 50226606

Tax ID: SK2120231828

Phone: +421 910 484 800

E-mail: office@rbl-trade.com

Web: www.rbl-trade.com

In situations where water infiltrates a house (for example, during floods or due to heavy rainfall), serious structural problems or health complications caused by mold growth may arise. For the product to be effective in combating these unwanted complications, it is not enough for it to be merely water-repellent. Its functionality is significantly influenced by its vapor permeability. Both requirements are met by the plaster IZONIL Hard, which primarily consists of Portland cement, silica sand, and a unique additive called Izocomponent. It is reinforced with PP fibers and can be used in both interior and exterior applications. The plaster is non-toxic (suitable for direct contact with drinking water) and can also be applied to damp surfaces. Application can be done manually or with a plastering machine, and due to the excellent adhesion of this plaster, minimal waste is produced during its application.

Universal Application

|

|

TECHNICAL DATA

| Appearance/color | grey powder |

| Chemical composition | silica sand, Portland cement, Izocomponent additive, PP fibers |

| Grain size of sand | 0–0.6 mm / 0–2 mm |

| Packaging | 25kg paper bag |

| Shelf life of the product during storage |

at least 18 months if stored in a dry environment |

| Mixing ratio | 4–4.7 liters of clean water / 25 kg of dry plaster |

| Workability | at least 3 hours (at 20 °C) |

| Layer thickness | one layer from 10 to 15 mm, maximum 3 layers with a total thickness of 30 mm |

| Consumption/yield | 25 kg of dry plaster (i.e., 1 package) is sufficient for an area: |

| • 1 m² at a layer thickness of 20 mm, OR | |

| • 2 m² at a layer thickness of 10 mm |

PARAMETERS TESTED ACCORDING TO EN 998-1:2016

| PROPERTY | DETERMINED VALUE | TEST REGULATION |

| Flow of fresh mortar after mixing | 160 mm | EN 1015-3 |

| Workability time of fresh mortar | ≥ 180 min | EN 1015-9, method B |

| Bulk density of hardened mortar | 1600 kg/m³ ± 100 kg/m³ | EN 1015-10 |

| Compressive strength (after 28 days) | ≥ 6 N/mm² (CS IV) | EN 1015-11 |

| Bending tensile strength (after 28 days) | ≥ 1.6 N/mm² | EN 1015-11 |

| Adhesion of hardened mortar to the substrate | ≥ 0.3 N/mm² – FP a) | EN 1015-12 |

| Capillary water absorption (R-remediation) | ≥ 0.3 kg/m² | EN 1015-18 |

| Capillary water absorption (GP) | W C 2 | EN 1015-18 |

| Water penetration after capillary water absorption test | ≤ 1 mm | EN 1015-18 |

| Water penetration under pressure 1 bar (after 72 hours) | ≤ 1 mm | EN 12390-8 |

| Thermal conductivity coefficient (tabulated value) | ≤ 0.45 W/mK (P = 50%) | EN 1745, tab. A.12 |

| Water vapor permeability coefficient (μ) | ≤ 8 | EN 1015-19 |

| Durability (freezing/thawing coefficient after 10 cycles) |

> 0.85 | STN 72 2452 |

| Reaction to fire | A2 – s1, d0 | without testing |

| Release of harmful substances into the environment | existence of BL | control of BL |

| Mass activity 226 Ra | 9.0 ± 1.6 Bq/kg | gamma spectrometric determination |

| Mass activity index | < 1 | gamma spectrometric determination |

Distributor for the Czech Republic and Slovakia:

RBL Trade s. r. o.

Štefánikova 81

085 01 Bardejov

Slovakia

Company ID: 50226606

Tax ID: SK2120231828

Phone: +421 910 484 800

E-mail: office@rbl-trade.com

Web: www.rbl-trade.com

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment