Clay plasters for the restoration of monuments and healthy new buildings

From October 5 to 8, a workshop on clay plasters and other technologies related to earthen buildings took place. The event was organized by the Clay Building Association, the company HLINĚNÝ DŮM Marek Vlček, and the company RIGI.

The goal of the event was to popularize the use of clay materials in construction and inform participants about the possibilities of applying clay in building structures.

Theoretical lectures focused on the development of earthen construction in Europe and in our country, the incorporation of earthen materials into low-energy buildings, and the use of clay in the renovation of heritage sites. Most participants actively engaged in practical demonstrations of working with clay, and for many of them, the opportunity to "handle" this material motivated their participation in the meeting.

This course was organized and conducted by instructors and collaborators from HLINĚNÝ DŮM and took place at the straw house, No. 33, in Lysovice.

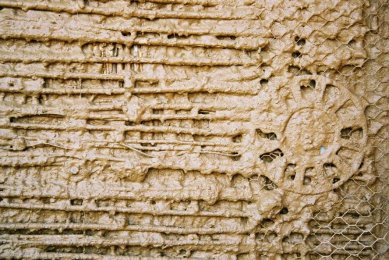

Preparation for the restoration of the original clay plasters began several days before the workshop itself. Due to the problematic condition of the masonry under the non-original lime plaster, this layer was not removed, but the implementation company attached reed mats, 2.5 cm thick, with sparse reed netting secured to the wall with large plates. A layer of adhesive clay undercoat ("spray") was applied to this prepared substrate, and after drying, a layer of coarse clay plaster with straw chaff will be applied. The final layer of fine clay mortar with barley chaff will be pressed into the damp material (the so-called "terkování"). A plastic facade with arched motifs, which is a traditional element of folk architecture in this region, will be created.

The design and project were developed by Ing. arch. Edita Vlčková after consultations and approval procedures with employees of SPÚ in Brno, Phdr. Věra Kovářů, and Mgr. Alena Dunajová.

House No. 33 in Lysovice is a significant cultural monument of folk architecture with its original layout preserved from this medium-sized agricultural estate.

During Thursday afternoon, gradually arriving participants engaged in preparatory work, settled in, and in the evening, while sitting together, shared what prompted them to attend this event.

On Friday afternoon, the areas and topics of practical demonstrations and implementations of clay technologies were specified and published.

In the morning, a series of lectures and thematic contributions on natural buildings and other natural materials took place.

Doc. Ing. Ivana Žabičková, chairwoman of the Clay Building Association, particularly mentioned the direction and development of earthen buildings in our country and other European countries, the possibilities of collaboration, and the necessity of incorporating this alternative into educational programs, testing laboratories, and standards.

A long-time employee of SPÚ in Brno and an indefatigable promoter of clay technologies in folk buildings, Ms. PhDr. Věra Kovářů, introduced the attendees to the issues of maintenance and restoration of earthen buildings from the perspective of heritage care. Various traditional methods mentioned during this lecture were presented in the evening screening of the film HLINĚNÝ DŮM. The content of the film, produced by the Institute of Folk Culture in Strážnice, includes examples of manual brick production, rammed earth walls, rolled walls, various types of clay plasters, chinking of log constructions, and laying pavement in beds of clay mortar.

Another contribution was made by Mr. Michal Navrátil from RIGI and his project Sluneční ulice near Tišnov. This exceptional initiative includes studies, an implementation project, and the realization of a complex of low-energy houses set in a beautiful natural environment with maximum use of natural materials.

Participants were intrigued by the structure and appearance of the used reed materials, and Mr. Pavel Otáhal, representing sales and implementation of these materials in the Czech Republic, indicated other possible uses such as insulation, in façade systems, for decorative purposes, and to create aesthetically valuable roofing with long durability.

Among the participants who joined the subsequent discussions were also representatives from PÚ and museums, where the use of clay also has its place.

There is reason to contemplate whether this topic is given adequate attention from a nationwide perspective. For the maintenance and restoration of folk architecture buildings, where clay has an irreplaceable role, a methodology should be developed, and the technological laboratory of SPÚ could devote equal attention to clay as it does to other building materials and methods research.

After being divided into individual workstations, practical demonstrations of working with clay began in the afternoon. In addition to the aforementioned restoration of the facade, clay mortar was used to repair plaster with arched relief on the embankment and subsequently coated with lime milk.

Lime coatings are suitable as surface finishes for clay plasters, especially for heritage buildings.

Coarse clay plasters with straw chaff were applied at another workstation onto unfired bricks using hands and wooden trowels, but only in areas where old plasters had been destroyed. Larger gaps in the masonry were filled with plugs made from unfired bricks laid in clay mortar. Before applying plasters, it is important to prepare the masonry so that the coarse mortar adheres as well as possible to the substrate. Preparation for old walls involves removing remnants of the original non-cohesive plaster, jointing the masonry, and applying an adhesive undercoat or spray. After the undercoat has dried, it is possible to start applying coarse plasters.

For the application of clay plasters using masonry methods, the mixture was thrown with a trowel into plastering machines and the surface was pulled with battens, using clay plasters without adding organic fillers. The substrate was a wall made of fired bricks adjusted by jointing and an adhesive spray.

In the stables, fine plasters were applied onto already dried coarse plasters. Plastic trowels were used for applying, and after it began to set, the surface was finished with sponge trowels. The final surface structure can be influenced by tightening techniques.

Work at the mentioned workstations continued the next day. On Saturday, students from FA VUT in Brno visited the course, where under the guidance of Doc. Hana Urbášková and Ing. Lukáš Sochor, they conducted architectural surveys in the Větrník microregion.

Another practical demonstration was the manual production of unfired bricks. The initial material in this case was recycled material from the rolled wall built three years ago in the garden.

This material was crushed and, after adding water, mixed in a kneading machine to the desired density. The resulting clay dough was pressed into a wooden mold. After its removal, the pressed brick was set aside to dry. The ability to easily recycle used materials is another important feature, in this case relating the construction to the environment. Participants then had the opportunity to compare their results with already completed bricks, both industrially and handmade.

After finishing work at the stations, interested parties could view the interior of the house, and those who stayed shared their opinions and experiences after a light dinner.

The aim of the organizers was primarily to highlight the various possibilities for processing clay mixtures.

Traditional mixtures of clay, sand, and chaff were mixed in a kneading machine or with a two-handed mixer. Mixtures intended for masonry processing and fine plasters can be mixed in a drum mixer.

It was also emphasized that quality building materials can be achieved in various ways. Either by utilizing the available local raw material, practical experimentation with this material, testing, and subsequent implementation, or by using pre-mixed mixtures with clearly defined properties, recommended technological procedures, and thus a predictable result.

Again, it is up to the builder to decide whether to create plasters or entire earthen structures on their own or to outsource these tasks to a specialized company. Another option is to train masons or plasterers who work with conventional materials.

Throughout the entire course, Czech industrially produced bagged clay plasters developed in collaboration between the companies Hliněný dům and RIGI were used.

On Sunday morning, various types of coatings for clay plasters were also mentioned, with particular emphasis on casein paints, lime coatings, and natural oils.

It was also pointed out that jute fabric can be used in clay plaster as a reinforcement element in exposed areas (reveals, corners, wall heating), which will improve the resulting properties of the structure while adhering to the principle of fully utilizing natural materials. However, practical demonstrations of these procedures could not be realized within the course but were carried out subsequently. Another difference when using clay mixtures compared to conventional materials is the significantly longer technological breaks between individual plaster layers.

On behalf of the organizers, we thank all participants not only for their hard work but also for the atmosphere they created. We would also appreciate your feedback or comments. We hope this meeting was beneficial and inspiring for its participants, and that it can be followed up in future courses related to earthen construction and broader use of natural materials in buildings.

> additional information at www.hlinenydum.cz

> photographs by Aleš Dorazil

The goal of the event was to popularize the use of clay materials in construction and inform participants about the possibilities of applying clay in building structures.

Theoretical lectures focused on the development of earthen construction in Europe and in our country, the incorporation of earthen materials into low-energy buildings, and the use of clay in the renovation of heritage sites. Most participants actively engaged in practical demonstrations of working with clay, and for many of them, the opportunity to "handle" this material motivated their participation in the meeting.

This course was organized and conducted by instructors and collaborators from HLINĚNÝ DŮM and took place at the straw house, No. 33, in Lysovice.

Preparation for the restoration of the original clay plasters began several days before the workshop itself. Due to the problematic condition of the masonry under the non-original lime plaster, this layer was not removed, but the implementation company attached reed mats, 2.5 cm thick, with sparse reed netting secured to the wall with large plates. A layer of adhesive clay undercoat ("spray") was applied to this prepared substrate, and after drying, a layer of coarse clay plaster with straw chaff will be applied. The final layer of fine clay mortar with barley chaff will be pressed into the damp material (the so-called "terkování"). A plastic facade with arched motifs, which is a traditional element of folk architecture in this region, will be created.

The design and project were developed by Ing. arch. Edita Vlčková after consultations and approval procedures with employees of SPÚ in Brno, Phdr. Věra Kovářů, and Mgr. Alena Dunajová.

House No. 33 in Lysovice is a significant cultural monument of folk architecture with its original layout preserved from this medium-sized agricultural estate.

During Thursday afternoon, gradually arriving participants engaged in preparatory work, settled in, and in the evening, while sitting together, shared what prompted them to attend this event.

On Friday afternoon, the areas and topics of practical demonstrations and implementations of clay technologies were specified and published.

In the morning, a series of lectures and thematic contributions on natural buildings and other natural materials took place.

Doc. Ing. Ivana Žabičková, chairwoman of the Clay Building Association, particularly mentioned the direction and development of earthen buildings in our country and other European countries, the possibilities of collaboration, and the necessity of incorporating this alternative into educational programs, testing laboratories, and standards.

A long-time employee of SPÚ in Brno and an indefatigable promoter of clay technologies in folk buildings, Ms. PhDr. Věra Kovářů, introduced the attendees to the issues of maintenance and restoration of earthen buildings from the perspective of heritage care. Various traditional methods mentioned during this lecture were presented in the evening screening of the film HLINĚNÝ DŮM. The content of the film, produced by the Institute of Folk Culture in Strážnice, includes examples of manual brick production, rammed earth walls, rolled walls, various types of clay plasters, chinking of log constructions, and laying pavement in beds of clay mortar.

Another contribution was made by Mr. Michal Navrátil from RIGI and his project Sluneční ulice near Tišnov. This exceptional initiative includes studies, an implementation project, and the realization of a complex of low-energy houses set in a beautiful natural environment with maximum use of natural materials.

Participants were intrigued by the structure and appearance of the used reed materials, and Mr. Pavel Otáhal, representing sales and implementation of these materials in the Czech Republic, indicated other possible uses such as insulation, in façade systems, for decorative purposes, and to create aesthetically valuable roofing with long durability.

Among the participants who joined the subsequent discussions were also representatives from PÚ and museums, where the use of clay also has its place.

There is reason to contemplate whether this topic is given adequate attention from a nationwide perspective. For the maintenance and restoration of folk architecture buildings, where clay has an irreplaceable role, a methodology should be developed, and the technological laboratory of SPÚ could devote equal attention to clay as it does to other building materials and methods research.

After being divided into individual workstations, practical demonstrations of working with clay began in the afternoon. In addition to the aforementioned restoration of the facade, clay mortar was used to repair plaster with arched relief on the embankment and subsequently coated with lime milk.

Lime coatings are suitable as surface finishes for clay plasters, especially for heritage buildings.

Coarse clay plasters with straw chaff were applied at another workstation onto unfired bricks using hands and wooden trowels, but only in areas where old plasters had been destroyed. Larger gaps in the masonry were filled with plugs made from unfired bricks laid in clay mortar. Before applying plasters, it is important to prepare the masonry so that the coarse mortar adheres as well as possible to the substrate. Preparation for old walls involves removing remnants of the original non-cohesive plaster, jointing the masonry, and applying an adhesive undercoat or spray. After the undercoat has dried, it is possible to start applying coarse plasters.

For the application of clay plasters using masonry methods, the mixture was thrown with a trowel into plastering machines and the surface was pulled with battens, using clay plasters without adding organic fillers. The substrate was a wall made of fired bricks adjusted by jointing and an adhesive spray.

In the stables, fine plasters were applied onto already dried coarse plasters. Plastic trowels were used for applying, and after it began to set, the surface was finished with sponge trowels. The final surface structure can be influenced by tightening techniques.

Work at the mentioned workstations continued the next day. On Saturday, students from FA VUT in Brno visited the course, where under the guidance of Doc. Hana Urbášková and Ing. Lukáš Sochor, they conducted architectural surveys in the Větrník microregion.

Another practical demonstration was the manual production of unfired bricks. The initial material in this case was recycled material from the rolled wall built three years ago in the garden.

This material was crushed and, after adding water, mixed in a kneading machine to the desired density. The resulting clay dough was pressed into a wooden mold. After its removal, the pressed brick was set aside to dry. The ability to easily recycle used materials is another important feature, in this case relating the construction to the environment. Participants then had the opportunity to compare their results with already completed bricks, both industrially and handmade.

After finishing work at the stations, interested parties could view the interior of the house, and those who stayed shared their opinions and experiences after a light dinner.

The aim of the organizers was primarily to highlight the various possibilities for processing clay mixtures.

Traditional mixtures of clay, sand, and chaff were mixed in a kneading machine or with a two-handed mixer. Mixtures intended for masonry processing and fine plasters can be mixed in a drum mixer.

It was also emphasized that quality building materials can be achieved in various ways. Either by utilizing the available local raw material, practical experimentation with this material, testing, and subsequent implementation, or by using pre-mixed mixtures with clearly defined properties, recommended technological procedures, and thus a predictable result.

Again, it is up to the builder to decide whether to create plasters or entire earthen structures on their own or to outsource these tasks to a specialized company. Another option is to train masons or plasterers who work with conventional materials.

Throughout the entire course, Czech industrially produced bagged clay plasters developed in collaboration between the companies Hliněný dům and RIGI were used.

On Sunday morning, various types of coatings for clay plasters were also mentioned, with particular emphasis on casein paints, lime coatings, and natural oils.

It was also pointed out that jute fabric can be used in clay plaster as a reinforcement element in exposed areas (reveals, corners, wall heating), which will improve the resulting properties of the structure while adhering to the principle of fully utilizing natural materials. However, practical demonstrations of these procedures could not be realized within the course but were carried out subsequently. Another difference when using clay mixtures compared to conventional materials is the significantly longer technological breaks between individual plaster layers.

On behalf of the organizers, we thank all participants not only for their hard work but also for the atmosphere they created. We would also appreciate your feedback or comments. We hope this meeting was beneficial and inspiring for its participants, and that it can be followed up in future courses related to earthen construction and broader use of natural materials in buildings.

> additional information at www.hlinenydum.cz

> photographs by Aleš Dorazil

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment