The facade is better protected against impacts and weather influences by Ceresit CT 85 mortar

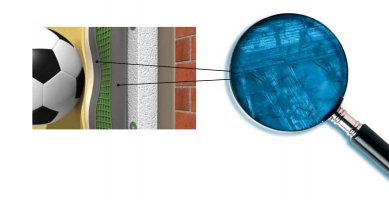

The adhesive and plaster mortar Ceresit CT 85 is modified with three reinforced types of microfibers and due to their unique combination and structure (mutual interactions and optimal lengths of individual microfibers), it is more resistant to rapid drying and subsequent formation of shrinkage cracks or cracking. The Ceresit Ceretherm façade thermal insulation systems, of which Ceresit CT 85 is a part, demonstrate greater impact resistance when all layers of the system are properly applied.

Ceresit CT 85 is water-resistant and frost-resistant and exhibits high adhesion to mineral substrates and polystyrene. Besides increased resistance to rapid drying and crack formation, it is also resistant to weather influences, particularly very low and very high temperatures. Its characteristics also include vapor permeability and flexibility. The mortar withstands challenging conditions during application very well – for example, direct strong sunlight and wind, thereby reducing the risk of facade damage.

Ceresit CT 85 is another example of Henkel's strong innovative potential, and its manufacturer is responding to the increasing market demands and high quality standards of contemporary ETICS systems with this product. Due to its greater resistance to mechanical impacts and external damage, the Ceresit Ceretherm façade systems are not only insulation systems but also provide an aesthetically perfect appearance for the building.

The Ceresit Ceretherm thermal insulation system with adhesive mortar Ceresit CT 85 was, for example, used on the facade of the spinal unit at FN Brno Bohunice - on an area of approximately 3,200 m² (2,000 m² of which were insulated), Henkel-Ceresit coatings, adhesive mortars, and pigmented pasty plasters were used. According to the recommendations of the technical advisors of Henkel Czech Republic, the Ceresit Ceretherm Wool Classic thermal insulation system was used for the spinal unit, which has been verified as resistant to biological attack, stronger impacts, weather influences and in the variant with mineral plaster meets fire classification A1 (non-combustible). This system is used for both new buildings and reconstructions of facades, for example, for facilities with strict fire requirements, including high-rise buildings and public buildings (schools, hospitals, shopping centers, gyms, entertainment centers, etc.). The final facade surface finish was realized with the silicon plaster Ceresit CT 74, which is supplied in more than 250 shades and is suitable for use in places where high vapor permeability is desired. Its further characteristic properties include resistance to weather influences, pollution, and biological attacks.

http://www.ceretherm.cz/ceresit-ct-85/

http://www.ceretherm.cz/ceresit-ct-84-express/