Enterprise

Upper station of the cable car with infocentre

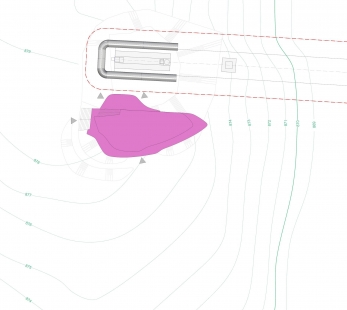

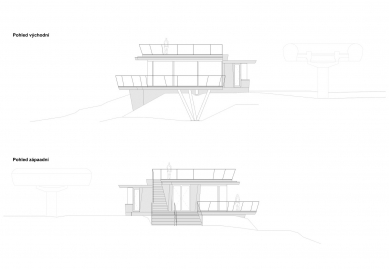

Enterprise - the first architectural realization using large-scale 3D concrete printing (3DCP) in a public mountain environment. Its sculptural form, inspired by the raw geological formations, acts both as a technological prototype and as a deliberate integration of architecture into the landscape.

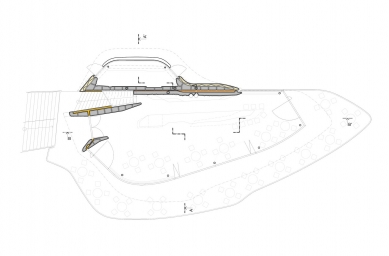

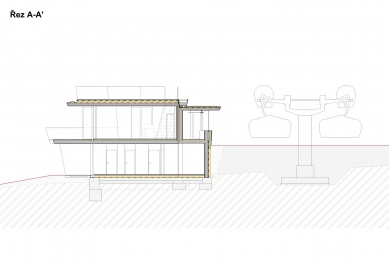

The building includes a control room, an information center, a green roof with a rooftop viewing platform, and public restrooms and storage facilities. The architecture merges printed concrete shells with integrated thermal insulation and carefully shaped terrain, forming a natural dialogue with its alpine setting.

3DCP technology manifests not only as a sustainable construction method, but also as a new architectural language – enabling ergonomic shaping, structural optimization, and the precise articulation and integration of spatial elements.

The centerpiece of the interior - the main counter of the information center - is designed as a lightweight printed lace, reflecting the morphology of the surrounding landscape, uniting ornament and tectonic logic.

The project faced exceptionally demanding construction conditions, including steep terrain and the requirement to maintain uninterrupted cable car operation throughout the build. The structural components were printed off-site in a fabrication hall, while rapid on-site assembly ensured minimal disruption.

The control cabin was assembled on the foundation within a single week, and the cable car was returned to full operation just three weeks after the foundation was laid. Enterprise is more than a technical station - it is a place for pause, perspective, and experience. It demonstrates how material experimentation and formal innovation can coexist in harmony with ecological sensitivity and poetic expression.

author's report

The building includes a control room, an information center, a green roof with a rooftop viewing platform, and public restrooms and storage facilities. The architecture merges printed concrete shells with integrated thermal insulation and carefully shaped terrain, forming a natural dialogue with its alpine setting.

3DCP technology manifests not only as a sustainable construction method, but also as a new architectural language – enabling ergonomic shaping, structural optimization, and the precise articulation and integration of spatial elements.

The centerpiece of the interior - the main counter of the information center - is designed as a lightweight printed lace, reflecting the morphology of the surrounding landscape, uniting ornament and tectonic logic.

The project faced exceptionally demanding construction conditions, including steep terrain and the requirement to maintain uninterrupted cable car operation throughout the build. The structural components were printed off-site in a fabrication hall, while rapid on-site assembly ensured minimal disruption.

The control cabin was assembled on the foundation within a single week, and the cable car was returned to full operation just three weeks after the foundation was laid. Enterprise is more than a technical station - it is a place for pause, perspective, and experience. It demonstrates how material experimentation and formal innovation can coexist in harmony with ecological sensitivity and poetic expression.

author's report

1 comment

add comment

Subject

Author

Date

Gratuluji k realizaci

Jiří Beran

08.01.26 09:31

show all comments