Villa Welpeloo

|

2012Architecten

Erik Stekelenburg describes the construction of this first villa by 2012Architects as an inverse explosion, since most of the constituent materials were obtained from the surroundings of the buildingsite. The comparison suits very well since the constructionsite of Villa welpeloo was devestated by the fireworks explosion in 2000 in Enschede.

Materials used:

Exterior

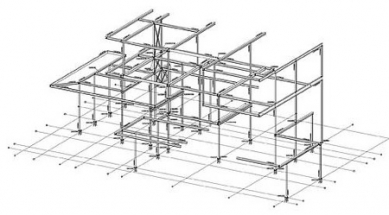

primary construction:redundant textile machine

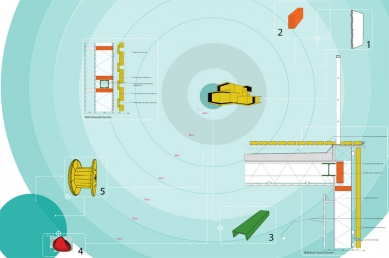

secondary construction: second hand wooden beams

floors and roof: dismanteledwooden floorboards

insulation: EPS-sheets from disassembly-site

cladding: wasted cable reels

moistregulation :seashells

foundation: concrete (sorry, new)

Interior

elevator: second hand construction-lift

shelvings: partly buildingsite-signs(waterproof multiplex)

lightfixtures: construction of broken umbrellaparts(by en-fer)

bathroom walls: smileplastic (compressed coffecups)

Environmental gain

co2 emissions including transport and processing:

cladding: 85% reduction compared to new simple wooden cladding

steel construction: 95% reduction compared to same construction with new steel

1 comment

add comment

Subject

Author

Date

X

Jan Pek

30.10.17 08:54

show all comments